Jyothy Puthumana, MD

- Assistant Professor

- Bluhm Cardiovascular Institute

- Northwestern University

- Feinberg School of Medicine

- Division of Cardiology

- Department of Medicine

- Chicago, Illinois

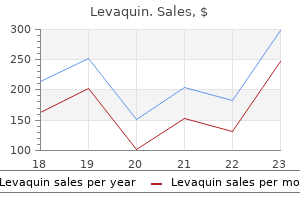

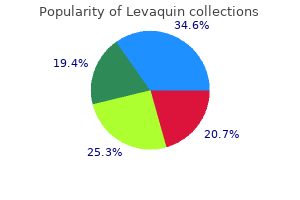

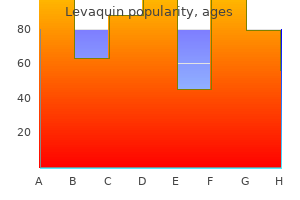

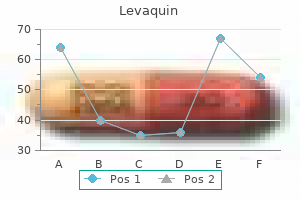

Levaquin dosages: 750 mg, 500 mg, 250 mg

Levaquin packs: 60 pills, 90 pills, 120 pills, 180 pills, 360 pills

Order levaquin 750mg with amex

Ear powders normally need to comply with the pharmaceutical requirements for powders for cutaneous software. Preparations requiring additional therapy on the time of dishing out Some preparations for oral use are prepared from powders or granules to yield oral options or suspensions utilizing a suitable car. This may be carried out at the dispensing stage or by the patient previous to administration. The vehicle for any preparations for oral use is chosen with regard to the character of the lively substance(s) and such that it provides organoleptic traits acceptable to the meant use of the preparation. Powders and granules for solution or suspension Powders and granules for the preparation of oral solutions or suspensions generally conform to the definitions in the normal pharmacopoeial requirements for oral powders or granules as applicable. They may comprise excipients, particularly to facilitate dispersion or dissolution and to stop caking. After dissolution or suspension, the resulting product ought to 482 taking capsules and tablets. Unfortunately, many antibiotics are physically or chemically unstable when formulated as a solution or suspension. The methodology used to overcome this instability downside is to manufacture the dry ingredients of the meant liquid preparation in an appropriate container within the type of a powder or granules. When the product is allotted, a given amount of water is added to reconstitute the answer or suspension. This enables sufficient time for warehousing and distribution of the product and storage at the pharmacy with out degradation. Amoxicillin Oral Suspension and Erythromycin Ethyl Succinate Oral Suspension are examples. Powders for oral drops Oral drops are solutions, emulsions or suspensions which might be administered in small volumes, such as in drops, by the means of an appropriate gadget. Powders for the preparation of oral drops must conform to the necessities of all other oral powders. After dissolution or suspension, they adjust to the specific pharmacopoeial requirements for preprepared oral drops. If the dose is measured in drops, the label must also state the number of drops per millilitre or per gram of preparation. Powders for injection Injections of medicaments which may be unstable in aqueous answer have to be made instantly prior to administration. Powders for injection are most frequently manufactured by a freeze-drying course of (see Chapter 29). The label for powders for injection ought to state (1) the quantity of lively ingredient contained within the sealed container, (2) the instructions for making ready the injection or intravenous infusion from the powder and (3) that when dissolved or suspended, the preparation is intended for parenteral use. After every container has been shaken, it ought to be emptied as utterly as possible; the check is performed on the person contents. As an example, the British Pharmacopoeia defines an energetic substance as one the place a single dose of powder or granules incorporates an quantity of energetic substance lower than 2 mg, or lower than 2% of the whole mass of the single-dose preparation. Oral powders and granules equipped in multidose containers must comply with this check. The strategies of manufacture of granules are principally the identical irrespective of the destiny of the granules. However, within the context of producing tablets, the mechanical properties of the granules and subsequently the way in which in which they deform and bond are critical in the tableting process. Pharmacopoeial checks the pharmacopoeial checks for assessing the quality of most powdered and granular dosage forms are very comparable. The position of those checks is indicated by its title; particulars of procedures and standards may be discovered in the newest acceptable pharmacopeia. Single-dose oral powders should adjust to a pharmacopoeial check for uniformity of dosage units or, the place justified and licensed, with the checks for uniformity of content material and/or uniformity of mass. Pharmaceutical expertise of granule production Pharmaceutical granulation processes Granulation methods could be divided into two varieties: wet strategies, which use a liquid in the process, and dry methods, in which no liquid is used. Single-dose oral powders have to comply with a check for uniformity of mass of single-dose preparations. The widespread types used are diluents, which are used to produce a unit dose weight of appropriate dimension, and disintegrating agents, which are added to help the break-up of the granule when it reaches a liquid medium. An adhesive (also known as a binder) in the type of a dry powder may be added, notably if dry granulation is employed.

Levaquin 750 mg otc

Taking cinnarizine for example, it would be advantageous to formulate a softgel fill matrix that permits lipolysis to happen in the intestinal lumen due to the high drug solubility in lipolytic merchandise. Formulation A was prepared as a lipolysing formulation and formulation B was prepared as a nonlipolysing formulation, as demonstrated by the in vitro mannequin. Formulation A was composed of a digestible triglyceride oil, a hydrophilic surfactant and a lipophilic surfactant, which was chosen on the idea of its capacity to overcome the inhibitory results of the hydrophilic surfactant on the in vitro triglyceride lipolysis. In vitro, this formulation exhibited 79% lipolysis after 60 minutes compared with the digestible oil alone. It was proposed that the oil in formulation A, which varieties a nice oil-in-water emulsion on aqueous dilution, is rapidly digested, forming mixed intestinal micelles with endogenous bile. These micelles transport the drug to the intestinal membrane, the place the pH of the microclimate promotes micellar breakdown, facilitating enterocyte transport to the systemic circulation. In contrast, on dilution with aqueous fluids, formulation B forms a translucent microemulsion (as indicated by a blue tinge ensuing from the Tyndall effect). As a result of this formulation failing to endure lipolysis and thereby remaining unaffected by enzymic exercise, the drug is maintained inside the oil part, inhibiting the production of combined intestinal micelles, therefore restricting absorption of the drug. The significance of the lipolysis course of in enhancing the bioavailability of hydrophobic medication was investigated further in an in vivo study. This study in contrast the bioavailability of cinnarizine (30 mg) orally administered as a lipolysing formulation (formulation A) or a nonlipolysing formulation (formulation B) to six beagle dogs with a commercially obtainable tablet (formulation C). The area underneath the plasma concentration�time curve (0 h to 24 h) for formulation A compared with the pill preparation was considerably elevated by 64% and for formulation A compared with formulation B was elevated by 48%. The outcomes of this study have given valuable insight into the impact of the microemulsion formulation on absorption of a hydrophobic drug in the gastrointestinal tract, and data as to how the lipolysis course of could affect bioavailability (Lacy et al. More just lately, a number of studies have been carried out to improve the understanding of drug disposition from lipid-based formulation methods (Porter et al. Additional specification checks could also be added for certain excipients to guarantee manufacture of a high-quality softgel product. For instance, you will need to restrict certain trace impurities corresponding to aldehydes and peroxides that may be present in polyethylene glycol. The presence of high levels of these impurities offers rise to cross-linking of the gelatin polymer, resulting in nonsolubilization through additional polymerization. On extended storage, this can lead to sluggish dissolution of the capsule shell and subsequent retarded drug launch. Gelatin additionally requires cautious management of quality to ensure a manufacturable and steady product. The high quality of gelatin is controlled by parameters such because the viscosity of a sizzling answer and the Bloom strength of the gel. Appropriate control ranges for these parameters are established throughout process growth for each softgel product, and are applied in routine productionscale manufacture. Finished product testing Finished softgels are subjected to numerous exams in accordance with compendial requirements for unit dose capsule products. These usually embrace capsule look, energetic ingredient assay and associated substances assay, in addition to fill weight, content uniformity, microbiological testing and dissolution testing. Development of a dissolution take a look at utilizing traditional media could be a problem for sure softgel formulations, including those with oily fills or those which rely on physiological circumstances to release the drug. Some have argued that disintegration testing could also be extra appropriate for certain softgels (Han & Gallery, 2006), while others use surfactant-based or enzyme-based media to obtain full dissolution in vitro. In-process testing During the encapsulation course of, tests for the next parameters are performed: References Aboul-Einien, M. The impact of in-vivo lipolysis in enhancing the bioavailability of 624 orally administered cinnarizine in self-emulsifying oily vehicles. A danger based mostly method to in vitro performance testing: a case examine on the utilization of dissolution vs. Softgels: consumer perceptions and market impact relative to other oral dosage types. The pill formulation of lopinavir/ritonavir provides similar bioavailability to the soft-gelatin capsule formulation with much less pharmacokinetic variability and diminished meals effect. Pharmacokinetic comparison of an oral diclofenac potassium liquid-filled delicate gelatin capsule with a diclofenac potassium pill. Development of a self-emulsifying formulation that reduces the meals effect for torcetrapib.

Purchase levaquin with a mastercard

The sealed ampoule is opened by the lid being twisted off, and only a few particles are generated to contaminate the product. The disadvantages are that this can be a more pricey course of, and is suitable just for drug products formulated as easy options. A full comparability of glass and plastics as supplies for pharmaceutical packaging is offered in Chapter 46. To withdraw a dose from a vial, the cap is removed and the septum disinfected with a sterile alcohol wipe. A syringe and needle is used to puncture the rubber closure and take away the required quantity of product. The rubber septum is self-sealing to a excessive diploma, and so a couple of withdrawal can be produced from a vial. Products packaged in vials for a number of use will therefore incorporate a preservative to stop any Vials Vials are containers often manufactured from sort I glass with a reusable artificial rubber closure. Vials have advantages as containers as they allow a quantity of withdrawals and are made in sizes often starting from 5 mL to one hundred mL. Vials are sealed with a bromobutyl or chlorobutyl synthetic rubber (elastomer) closure held in place by an aluminium seal crimped across the neck of the glass vial. Synthetic rubber can be latex-free, which is necessary as sensitization to latex is an rising problem for health care employees. The primary drawback is that puncturing the rubber closure can cause giant rubber particles to be introduced into the drug product. Infusion bags and bottles Large-volume parenteral merchandise are packaged in glass bottles, collapsible plastic baggage and semirigid plastic bottles, although the utilization of glass bottles for large-volume parenteral merchandise is changing into much much less commonplace. Collapsible luggage often have an additive port to enable different injectable medicine to be added to the infusion fluid. Additionally, elements can leach out of the plastic, corresponding to monomers and phthalate plasticizers, which can be toxic on longterm exposure. These containers could have an additive port to enable other medication to be added to them. Large-volume glass bottles are basically the identical as glass vials however on a larger scale. Nowadays, parenteral merchandise may be packaged in syringes, and will thus be introduced to the health care professional or patient in a ready-to-use format. Such infusion units are used to administer drugs intravenously over a chronic interval. They are used for the administration of analgesia postoperatively (which the patient could management on demand) or as part of palliative care. Infusion devices can be battery-powered pumps which infuse medication from an connected plastic reservoir. When crammed, the balloon is tremendously expanded and the drug resolution inside is underneath strain. The benefit of elastomeric gadgets is that the mechanical stress from the inflated reservoir powers the gadget and no batteries are required. The drawback is that the circulate rate by way of the restriction valve is temperature delicate, so could be altered dependent on how the system is worn by the affected person. If the restriction valve is positioned next to the skin of the patient, a higher than expected flow price is seen. The administration of a drug at its web site of motion can end result in a rapid onset of exercise, which may be highly fascinating, as an example when bronchodilating drugs for the treatment of asthma are being delivered. The avoidance of first-pass (presystemic) metabolism within the liver may be advantageous, though the lung itself has some metabolic functionality. The lung can also be used as a route for delivering drugs having systemic activity, because of its large floor area, the abundance of capillaries and the thinness of the air�blood barrier. This has been exploited within the remedy of migraine with ergotamine and diabetes with insulin, and the potential for delivering biopharmaceuticals, such as insulin, vaccines and progress hormone, through the airways is now properly established. The structure of the airways also efficiently prevents the entry and promotes the elimination of airborne overseas particles, including microorganisms. The upper respiratory tract contains the nostril, throat, pharynx and larynx; the lower respiratory tract comprises the trachea, bronchi, bronchioles and the alveolar areas. Simplistically, the airways can be described by a symmetrical model during which each airway divides into two equivalent branches or generations.

Generic 500mg levaquin with visa

The dangers related to this invasive process embrace vitreous haemorrhage, cataract, retinal detachment and endophthalmitis. However, research have shown sufferers need cataract extraction and intraocular stress decreasing surgery. The Iluvien implant may be inserted into the vitreous humour via a 25-gauge needle; this contrasts with the A nonbioerodable intravitreal implant encased in a zero. Ongoing developments in this area embrace (1) a helical system, comprising a nonferrous steel scaffold coated with a polymer�drug matrix for the supply of triamcinolone acetonide administered by transconjunctival injection for diabetic macular oedema and (2) an implant containing genetically modified cells which produce growth components, together with ciliary neurotrophic factor. The pore measurement of the implant allows the growth factors to diffuse outwards into the eye and nutritional molecules to enter, however prevents the entry of antibodies or inflammatory cells that may attack the overseas genetically modified cells. Biodegradable intraocular implants Biodegradable systems are composed of polymers which are metabolized by enzymatic or nonenzymatic. Biodegradable polymers could be made into a selection of sizes and shapes, together with pellets, sheets, discs and rods, via totally different processes. Hot soften extrusion has been used whereby the polymer and drug are subjected to elevated temperature and strain, inflicting the polymer to endure melting whereas being 0. This entails the formation of a homogeneous resolution or dispersion of the polymer and drug in a solvent which is spread onto a flat floor. Freeze-drying is one other method employed, with the cake shaped being subsequently formed by heating and compression. Developing ocular biodegradable techniques is, nevertheless, more difficult as a mess of things must be considered, together with gadget stability, as nicely as erosion of the polymer and surface space adjustments which can affect in vivo kinetics. To extend the period of motion of corticosteroids in the vitreous cavity, intravitreal injection of a suspension of triamcinolone acetonide (Kenalog) has been used for many years off-label. Since the introduction of Ozurdex, preservative-free triamcinolone acetonide intravitreal injections, Triesence (Alcon Laboratories) and Trivaris (Allergan), have been registered to be used. One advantage of Ozurdex is that it displays an analogous pharmacokinetic profile between vitrectomized and nonvitrectomized eyes, whereas suspensions of triamcinolone acetonide clear extra shortly in vitrectomized eyes. Complete polymer degradation results in conversion to the unique monomers, lactic acid and/or glycolic acid, which are metabolized to carbon dioxide and water by the Krebs cycle. A 1: 1 ratio of lactic acid to glycolic acid provides the quickest biodegradation price; an increase or lower of the proportion of either monomer typically prolongs the degradation time. The first section is burst launch, whereby drug at the floor of the implant dissolves, making a excessive fee of drug launch in a brief interval. This burst release is more doubtless to be exacerbated if the system has a big floor space. The second section is the diffusive section involving drug dissolution and diffusion out of the matrix down a concentration gradient, which is ruled by drug solubility within the surrounding fluid. As water penetrates into the core, the implant swells and random hydrolytic cleavage of the polymer chains can also happen. Eventually bulk erosion in the core of the matrix causes the polymer chains to lose their structural integrity and mass loss occurs. This third part leads to fast launch of the remaining drug load when hydrolysis of the polymers reaches a threshold. Poly(-caprolactone) is of particular curiosity because it has a sluggish rate of degradation and can therefore be used to achieve extended drug launch for a year or more. It is presently used for sutures, synthetic pores and skin support and mobile regeneration. In a recent research, triamcinolone acetonide loaded poly(-caprolactone) implants were ready by homogeneous mixing of the drug and polymer in solvent adopted by solvent evaporation. The filaments fashioned had been a hundred and fifty �m in diameter and had been reduce into desired lengths of 2 mm. The rods have been implanted into the subretinal area, and drug launch was noticed for a minimum of 4 weeks. An initial part of quick drug launch followed by a pseudo-first-order launch was observed.

Buy levaquin 250 mg without a prescription

Multiphase suppositories containing mucoadhesive polymers combined in the base are additionally widespread. For instance, Gyno-Pevaryl Once (econazole nitrate) pessaries contain Witepsol and Wecobee fatty bases mixed with Polygel, which retains the molten base connected to the vaginal wall. The formulation issues and drug launch mechanisms from vaginal suppositories are related Semisolid vaginal preparations Semisolid vaginal preparations are often lotions or gels. They are intended for native or systemic drug supply, prevention of bacterial vaginosis by restoring the pH steadiness (lactic acid gel) and likewise for personal care of the vaginal area. For example, Canesintima Intimate Moisturiser is an aqueous gel enriched with Camellia japonica and hyaluronic acid for vaginal moisturization and lubrication intended for menopausal and postmenopausal girls. Semisolid formulations, because of their water content, are much less more doubtless to cause irritation of the vaginal wall than pessaries. Mucoadhesive polymers, similar to Carbopol, are sometimes included within the formulation to allow dosage form retention in the vaginal wall and prolonged drug release. Recent advances embody: � Thermoreversible mucoadhesive gels to allow easy insertion of the dosage kind. Clinical trials have demonstrated a greater immune response from a vaginal gel than for an orally administered cholera vaccine (Wassen et al. Rheological properties of the semisolid, spreading behaviour, volume, pH, osmolarity, ease of insertion and retention and patient acceptability are all parameters that have to be thought of for these preparations. Current analysis and improvement on vaginal films focuses on: � Reformulation of antifungal drugs. They comprise a drug reservoir within the polymer network and allow controlled drug launch over a chronic period. The first vaginal rings had been developed in the 1970s as contraceptive units (NuvaRing) and for the treatment of atrophic vaginitis (Estring) as part of hormone replacement remedy. In recent years, vaginal rings have attracted lots of attention as promising microbicide delivery techniques. A silicone vaginal ring designed to provide sustained dapivirine release over 28 days (Nel et al. More advanced formulations embrace multisegment vaginal rings (with hydrophilic and lipophilic polymer segments) which incorporate a combination of medicine with totally different physicochemical properties; this can be a mixture of two antiretroviral energetic components or a combination of an antiretroviral with a contraceptive (so-called dual-protection rings). Vaginal movies Vaginal movies are small, skinny polymeric layers, designed to dissolve in the vaginal fluids and launch the drug. They are single-dose preparations and may be simply inserted into the vaginal cavity without the necessity for an applicator. Because of their ease of administration, vaginal films tend to demonstrate greater patient acceptability than pessaries, semisolid vaginal formulations and vaginal rings. In terms of composition, the movies include polymers which can confer mucoadhesive and modified-release properties on the formulation. When involved with the vaginal fluids, they rapidly dissolve and turn to a mucoadhesive viscous resolution that attaches to the vaginal wall. They are supplied in single-dose containers designed to ship the preparation to the vagina, or are accompanied by a suitable applicator. Excipients could also be added to adjust the viscosity of the preparation and to adjust the pH in order to increase the solubility of the lively substance(s). Vaginal emulsions might present proof of section separation but are readily redispersed on shaking. Tablets for vaginal solutions and suspensions the tablets supposed for the preparation of vaginal solutions and suspensions are single-dose preparations which might be dissolved or dispersed in water on the time of administration. They might include excipients to facilitate dissolution or dispersion, or to stop caking. Medicated vaginal tampons Medicated vaginal tampons are solid, single-dose polymeric preparations meant to be inserted within the vagina for a restricted time and then removed. The drug is current in a matrix created from an acceptable polymer corresponding to silicone, cellulose or gelatin.

Order levaquin on line amex

In order to deal with a powder of acceptable flowability and bulk density, comparatively massive particles must be used which can be troublesome to mix to a excessive homogeneity and could additionally be prone to segregation. Moreover, a powder consisting primarily of a drug will be difficult to kind into tablets if the drug itself has poor compactability. Finally, a uniform colouring of tablets can be tough to obtain with a colourant in dry particulate kind. However, granules of top quality when it comes to homogeneity, flowability and compactability could be prepared by this operation. By spray-drying a suspension of drug particles in a liquid, which can contain a dissolved binder, relatively small spherical granules with uniform dimension may be ready. The course of is of limited use, except for the preparation of fillers or diluents for direct compaction. The granules can present good compactability, and this presents the risk of granulating a drug suspension and not using a separate drying step for the drug substance. The formation of granules by compacting the powder into large compacts that are subsequently comminuted into smaller granules is another strategy to granulation. The approach can be utilized as a way of avoiding exposure of the powder to moisture and warmth and can be referred to as dry granulation. In addition, for powders of very low bulk density, compaction can be an efficient means to improve markedly their bulk density. Depending on the supposed major perform, the excipients to be utilized in tablets are subcategorized into completely different groups. However, one excipient can affect the properties of a powder or the tablet in a number of methods, and many substances used in tablet formulations can thus be described as multifunctional. The capabilities of the most common kinds of excipients used in tablets are described in the following sections. Disintegrant Solution binder Dry binder Glidant Filler (or diluent) In order to kind tablets of a dimension appropriate for dealing with, a lower limit in terms of powder quantity and weight is required. Therefore a low dose of a potent drug requires the incorporation of a substance into the formulation to increase the majority volume of the powder and hence the dimensions of the pill. The perfect filler should fulfil a sequence of necessities, corresponding to: Lubricant Antiadherent � � � � be chemically inert; be nonhygroscopic; be biocompatible; possess good biopharmaceutical properties. Crystalline lactose is formed by precipitation and, relying on the crystallization circumstances, -monohydrate or -lactose (an anhydrous form) may be fashioned. By thermal remedy of the monohydrate form, crystalline -anhydrous particles can be prepared. Depending on the crystallization conditions and the usage of subsequent dimension discount by milling, lactose of different particle sizes is obtained. Amorphous lactose can be prepared by the spraydrying of a lactose resolution (giving almost fully amorphous particles) or a suspension of crystalline lactose particles in a lactose resolution (giving aggregates of crystalline and amorphous lactose). Amorphous lactose dissolves more rapidly than crystalline lactose and has higher compactability. Other sugars or sugar alcohols, corresponding to glucose, sucrose, sorbitol and mannitol, have been used as alternative fillers to lactose, primarily in lozenges or chewable tablets, due to their pleasant style. Mannitol has a negative warmth of solution and imparts a cooling sensation when sucked or chewed. Apart from the sugars, perhaps essentially the most widely used fillers are powdered celluloses of various sorts. Celluloses are biocompatible, are chemically inert and have good tablet-forming and disintegrating properties. They are appropriate with many drugs however, owing to their hygroscopicity, may be incompatible with medication susceptible to chemical degradation in the solid state. The most typical sort of cellulose powder utilized in pill formulation is microcrystalline cellulose. The name indicates that the particles have each crystalline and amorphous areas, relying on the relative position of the cellulose chains throughout the solid. The degree of crystallinity might differ relying on the supply of the cellulose and the preparation procedure. The diploma of crystallinity will have an effect on the bodily and technical properties of the particles.

Cheap 750 mg levaquin amex

Key variables to contemplate when designing dissolution tests are described within the following paragraphs. Although many kinds of dissolution apparatus can be found, the most generally used are compendial dissolution apparatus. These are standardized and sturdy dissolution testers described by pharmacopoeias. This refers to the mechanical agitation offered by the dissolution equipment which will assist in the dissolution of the drug. The varied dissolution apparatus provide totally different hydrodynamics, and these may be various to enable one of the best outcomes to be obtained. Devising a predictive dissolution test is extra challenging as biorelevant situations must be sought to mimic the physiological parameters which affect the dissolution of the drug in the gastrointestinal tract. The main issues in designing each forms of dissolution test methods are described within the following sections. As a basic rule, these strategies are of straightforward execution, reliable, reproducible, but sufficiently discriminatory to be able to detect small product deviations. The number of a dissolution apparatus depends mainly on the solubility of the drug and the kind of dosage kind. The reciprocating cylinder and flow-through cell techniques are significantly helpful for the testing of modified-release dosage types and poorly soluble medication respectively. Many pharmacopoeias worldwide define detailed specifications for traditional dissolution apparatus and methods. As a result of harmonization of those standards, most pharmacopoeial specifications are extremely similar. All main pharmacopoeias are very related, however even if the element differs, the Table 35. In this apparatus the dosage kind is positioned inside a rotating basket manufactured from a chrome steel wire mesh and immersed in dissolution medium, which has been prewarmed, at 37 �C. During the check the basket rotates at a constant pace, sometimes set between 50 and one hundred rpm. The dissolution medium is contained in a glass cylindrical vessel with a spherical backside and with a nominal capability of no less than 1 L. The composition and/or pH of the medium could additionally be modified by guide alternative of the medium or by adding media of different composition. At predetermined instances, samples of the dissolution medium are eliminated and analysed for drug content material. This function makes it significantly suited to estimate the drug release profile in several elements of the gastrointestinal tract as wanted in the case of modified-release formulations, corresponding to extendedrelease or gastro-resistant coated merchandise. During the test the inside cylinder is dipped vertically into the dissolution medium several occasions, creating convective forces for dissolution. It is usually thought-about that 5 dips per minute is equal to 50 rpm in the paddle apparatus. The internal cylinder is fitted with a mesh screen at the backside and top which allows the medium to flow into freely inside it, but prevents losses of finely disintegrated materials. In this apparatus the dosage form is positioned in a small-volume cell, on a glass bead bed or on a clip holder. The pattern under take a look at is subjected to a continuous flow of media in an upward course. The medium is pumped from a reservoir at a circulate rate which can vary from 5 mL min-1 to 20 mL min-1. The pulsating motion of the pump creates gentler hydrodynamics compared with other compendial apparatus (arguably extra just like the motion that would be experienced by a dosage form in the gut). The dissolution medium could be changed during the check by exchanging the media reservoirs. In the latter set-up, fresh dissolution medium is delivered constantly by the pump and collected for analysis after it has handed though the sample cell; this method is especially suitable for testing the dissolution of poorly soluble medication. It makes use of the same dissolution vessels because the basket apparatus but here the dosage type is positioned on the centre bottom of the vessel. Agitation is supplied by a metallic paddle which rotates at speeds between 50 and one hundred fifty rpm (most typically 50�75 rpm).

Buy line levaquin

There are two primary types of gelatin: kind A, which is produced by acid hydrolysis, and sort B, which is produced by primary hydrolysis. The acid course of takes roughly 7�10 days and is used primarily for porcine skins, as a outcome of they require less pretreatment than bones. The fundamental process takes about 10 occasions as lengthy and is used mainly for bovine bones. The bones should first be decalcified by washing in acid to give a soft sponge-like material, called ossein, and calcium phosphates are produced as a by-product. After hydrolysis, the gelatin is extracted from the handled materials utilizing scorching water. The first extracts contain the gelatin with the best bodily properties, and because the temperature is raised, the quality falls. The resulting weak resolution of gelatin is concentrated in a collection of evaporators and then chilled to form a gel. This gel is extruded to kind strands, which are then dried in a fluidized-bed system. The dried material is graded after which blended to meet the varied specs required. The properties of gelatin that are most essential for capsule producers are the Bloom energy and viscosity. It is outlined because the load in grams required to push a standard plunger four mm into the gel. The gelatin utilized in hard capsule manufacture is of a higher Bloom strength (200 g to 250 g) than that used for delicate capsules (150 g) as a end result of a extra rigid film is required for the manufacturing course of. Many supplies used within the manufacture of pharmaceuticals are manufactured from uncooked materials of bovine origin. Traditionally both include gelatin, water, colourants and optional materials, corresponding to course of aids and preservatives; in addition, soft capsules comprise varied plasticizers, such as glycerine and sorbitol. Since the late Nineteen Nineties, hard capsules have additionally been manufactured from hypromellose (hydroxypropyl methylcellulose) to be able to produce a shell with low moisture content. Gelatin and hypromellose Gelatin continues to be the main element used for capsules, but many new merchandise, particularly these utilized in dry powder inhalers, are produced from hypromellose. All polymer methods need to have the identical fundamental properties for the manufacture of capsules: 1. They are unhazardous (gelatin is extensively used in foodstuffs, and hypromellose is utilized in tablets for film coating) and are acceptable for use worldwide. A solution in water undergoes a reversible change from a sol to a gel at temperatures only a few levels above ambient temperature. Manufacturers of related materials need to submit data to the European Directorate for the Quality of Medicines & HealthCare, which can evaluation the info and problem a certificates of suitability for the product. This should then be submitted to the national regulatory authorities for medicinal products that contain these materials. Hypromellose is manufactured from cotton linters or wood by therapy with sodium hydroxide options and further chemical substances to produce methyl hydroxypropyl ethers. These are treated with hydrochloric acid to produce totally different viscosity grades (Rogers, 2012). Process aids the United States Pharmacopeia�National Formulary describes using gelatin containing not more than zero. This capabilities as a wetting agent, to be certain that the lubricated metallic moulds are uniformly coated when dipped into the gelatin solution. Preservatives were previously added to exhausting capsules as an in-process help in order to prevent microbiological contamination during manufacture. Hypromellose, due to its uncooked materials and processing, has low microbial levels, and capsules manufactured utilizing it have a decrease moisture specification than gelatin. Manufacture the process in use at present is similar as that described within the authentic patent of 1846.

Real Experiences: Customer Reviews on Levaquin

Mitch, 64 years: Above the cmc, micelles are fashioned with a hydrophobic core, and the hydrophobic drug will start to dissolve into this area, thus affecting the construction of the system. The identical applies for nebulizers, with modern designs tending to be smaller, more portable and extra appealing to youngsters than up to now. The attachment of monoclonal antibodies to reactive teams incorporated in the hydrophilic coating of polymeric micelles has also been investigated and shown to promote particular interplay of the micelles with antigens comparable to the antibodies.

Faesul, 33 years: This method, although extraordinarily useful, should be used with caution as the Gram reaction might vary with the age of the cells and the technique of the operator. The difference in bioavailability of the three solutions was attributed to the distinction in the rates of precipitation of the candidate drug from the three solutions on dilution. A cosolvent corresponding to ethanol or 2-propanol could additionally be used, though their low volatility retards propellant evaporation.

Denpok, 60 years: The drawback of applying the Heckel method to the compression of porous particles is related to the necessity to assess the porosity of the reactant pore system. Eye drops are difficult to administer and require coordination, manual dexterity and imaginative and prescient, necessitating clear directions and affected person counselling. An unsuitable pH, insufficient buffer or inadequate aeration could all limit the extent of progress, with the result that the cells that do grow every have available to them a better focus of vitamins than would be the case if the next cell density had been achieved.

Tukash, 58 years: Examples of thermoset polymers embrace urea formaldehyde, epoxides, urethanes, unsaturated polyesters and rubbers. Cells of pneumococci have been reported to survive dry heat at 110 �C for half-hour but this represents exceptional resistance for vegetative cells, most of which can be anticipated to die after a few minutes heating at one hundred �C or less. Gram-negative cell partitions are extra complex, comprising a a lot thinner layer of peptidoglycan surrounded by an outer bilayered membrane.

Hatlod, 54 years: The hypothalamus and pituitary gland are linked by necessary neurovascular connections. Thus variations in dissolution rate might be expected in numerous regions of the gastrointestinal tract. Because of the excessive surface area to quantity ratio offered by nanoparticles, the solubility and price of dissolution of medicine could be elevated.

9 of 10 - Review by Q. Rathgar

Votes: 243 votes

Total customer reviews: 243

References

- Editors: London Medical Review 1812;5:262.

- Valentine RJ, Rossi MB, Myers SI, et al. Splenic infarction after splenorenal arterial bypass. J Vase Surg. 1993;17:602-606.

- Gwyther LP. Care of Alzheimer's Patients: A Manual for Nursing Home Staff. Chicago: Alzheimer's Association and American Health Care Association; 1985:20-25.

- Sumi SM, Farrell DF, Knauss TA. Lymphoma and leukemia manifested by steroid-responsive polyneuropathy. Arch Neurol. 1983;40:577-582.